Model |

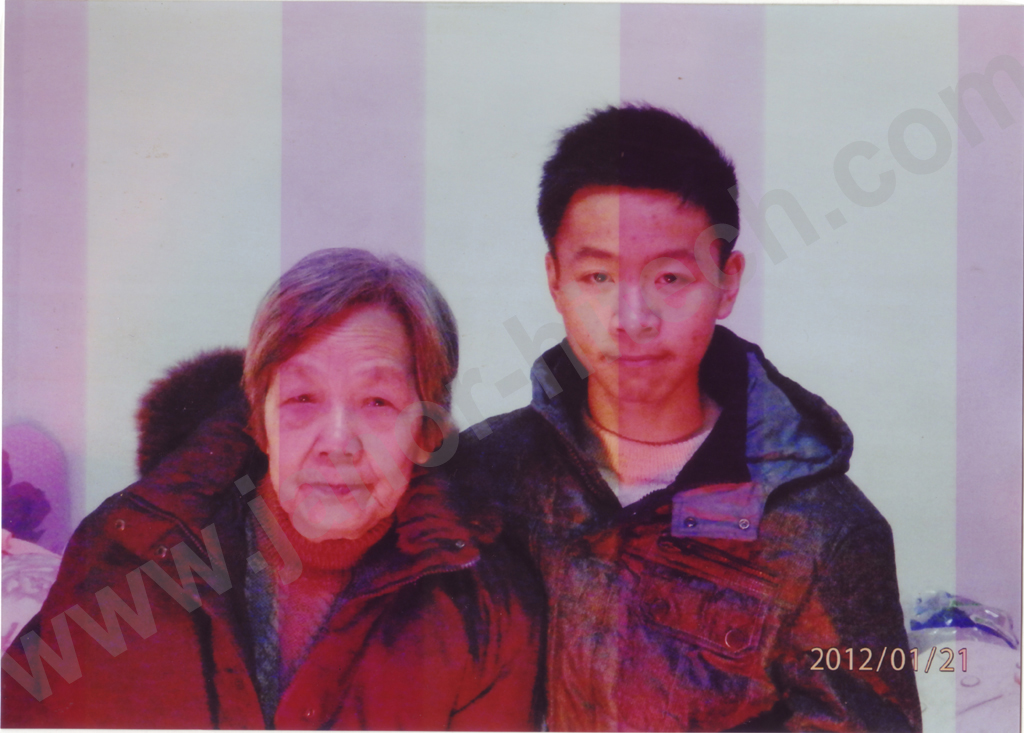

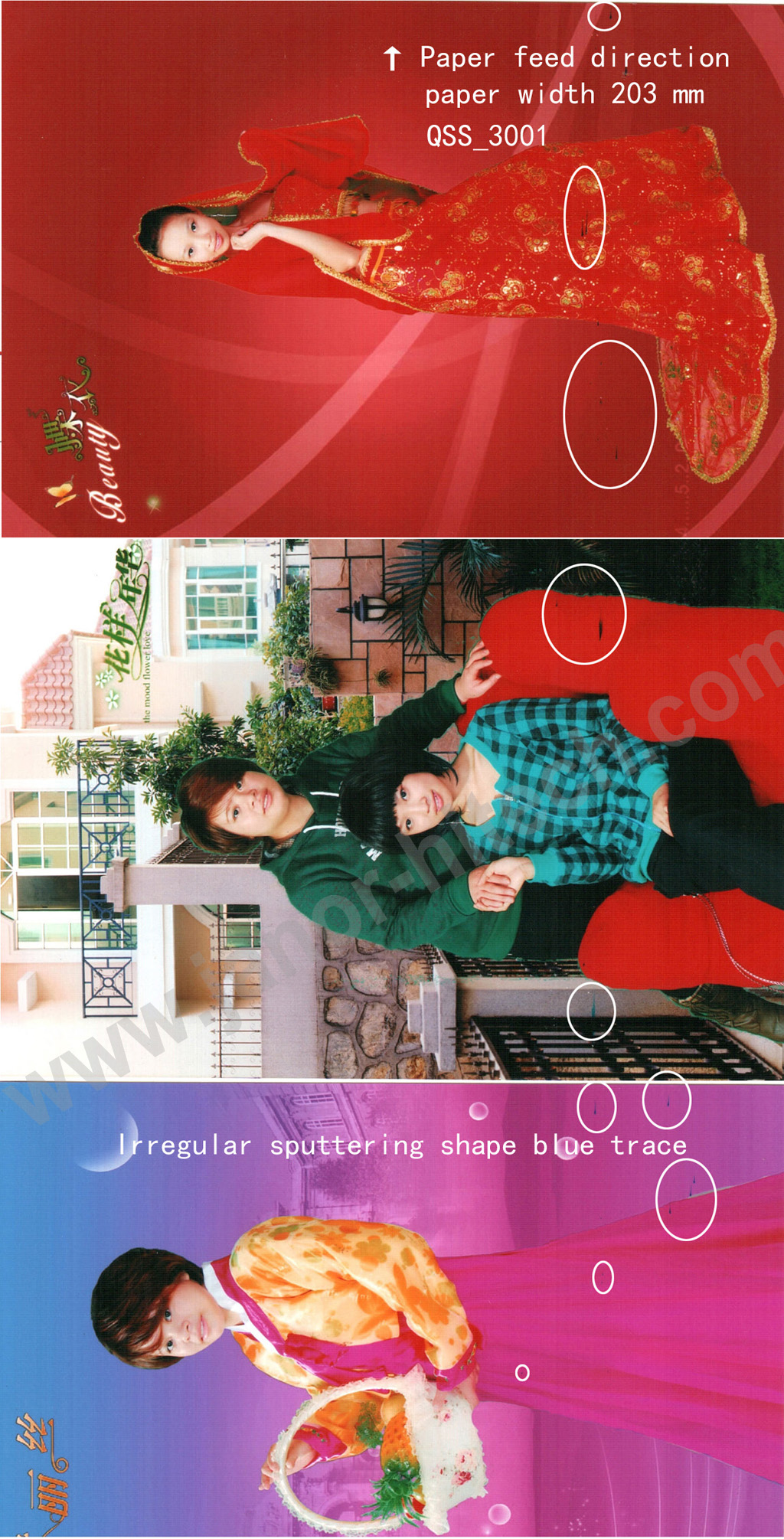

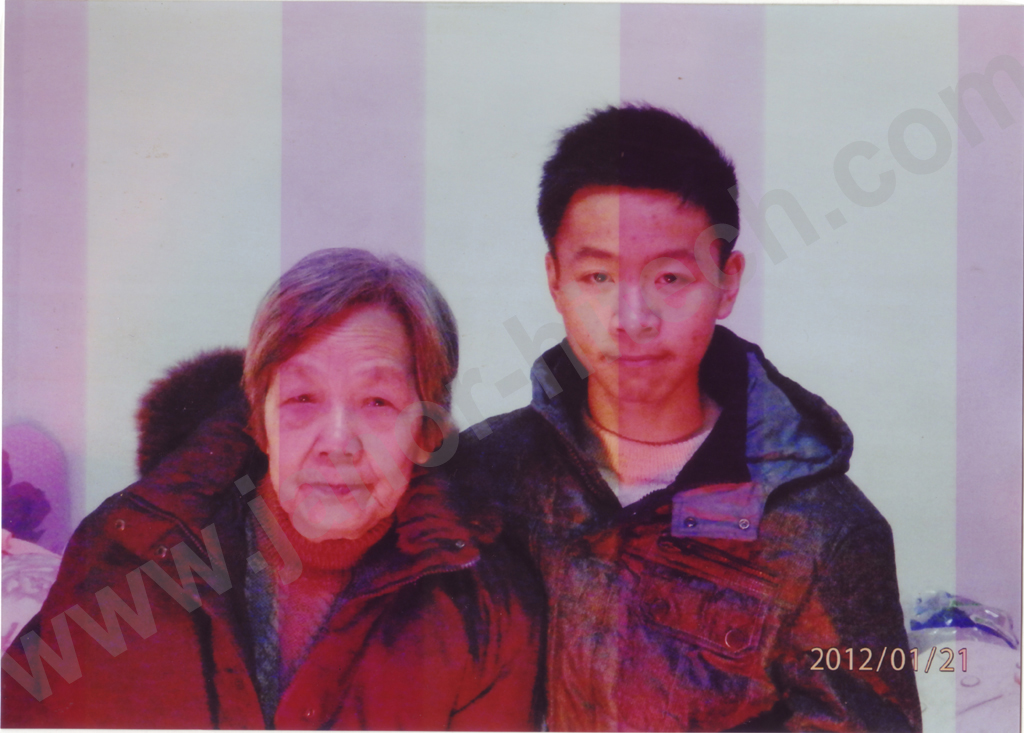

Error describe |

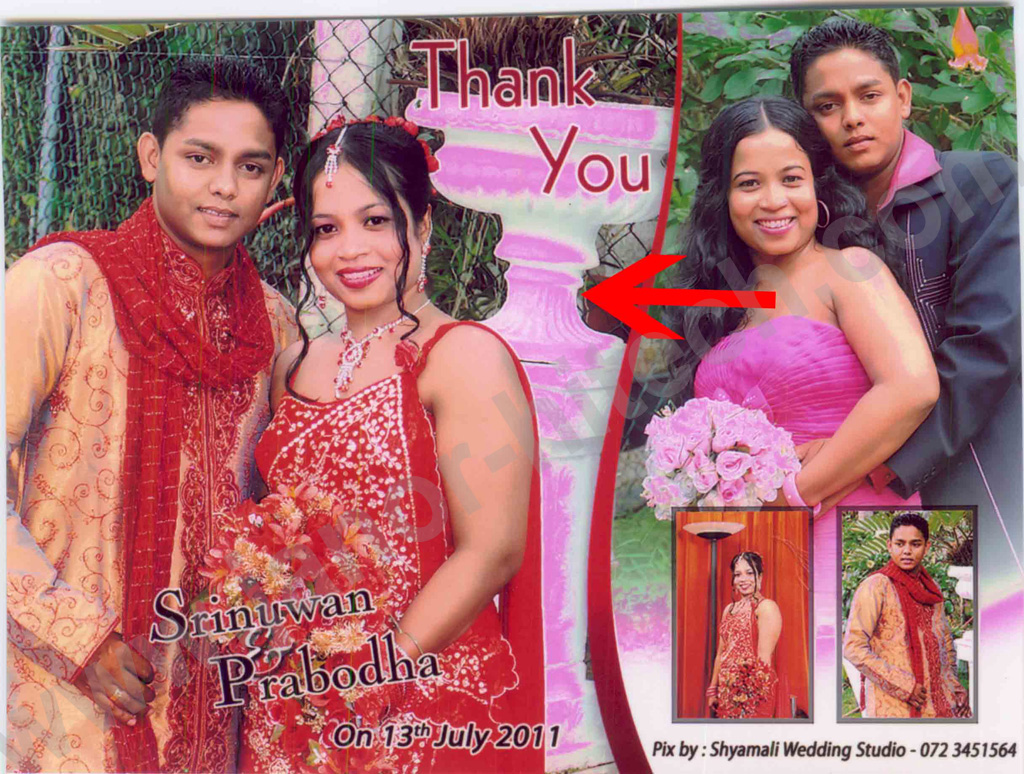

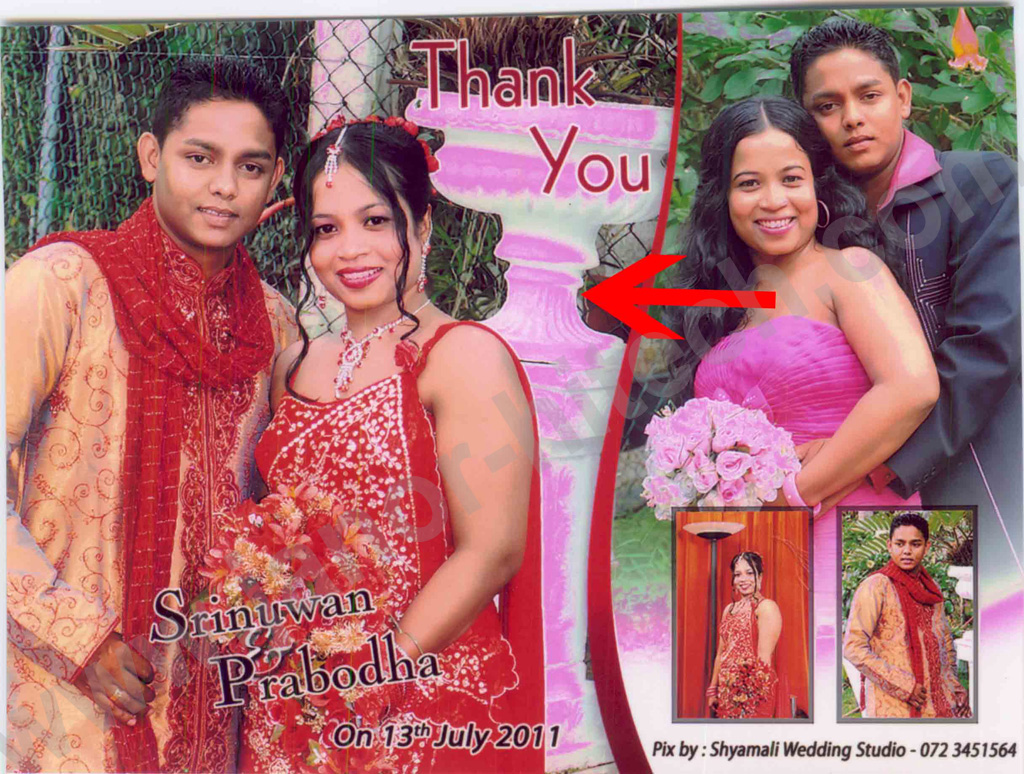

Sample print |

Cause |

ALL |

Color change |

|

AOM driver work is not stable, so,

the amount of light output to the photo change,

cause photo change color

(Cyclical change ) |

ALL |

Color change |

|

AOM driver work is not stable, so, the amount of light output to the photo change, cause photo change color

(Short lost output signal ) |

ALL |

Color change |

|

AOM driver work is not stable, so, the amount of light output to the photo change, cause photo change color

(Output slope not smooth ) |

ALL |

Color change |

|

If the color changed randomly,not regular,most likely the AMO driver was damaged. You can assure this by changing the AMO driver.

|

ALL |

Color shift |

|

AOM driver work is not stable, so, the amount of light output to the photo change, cause photo change color

(Output slope not smooth light) |

ALL |

Color shift |

|

AOM driver work is not stable, so, the amount of light output to the photo change, cause photo change color

(Output slope not smooth light) |

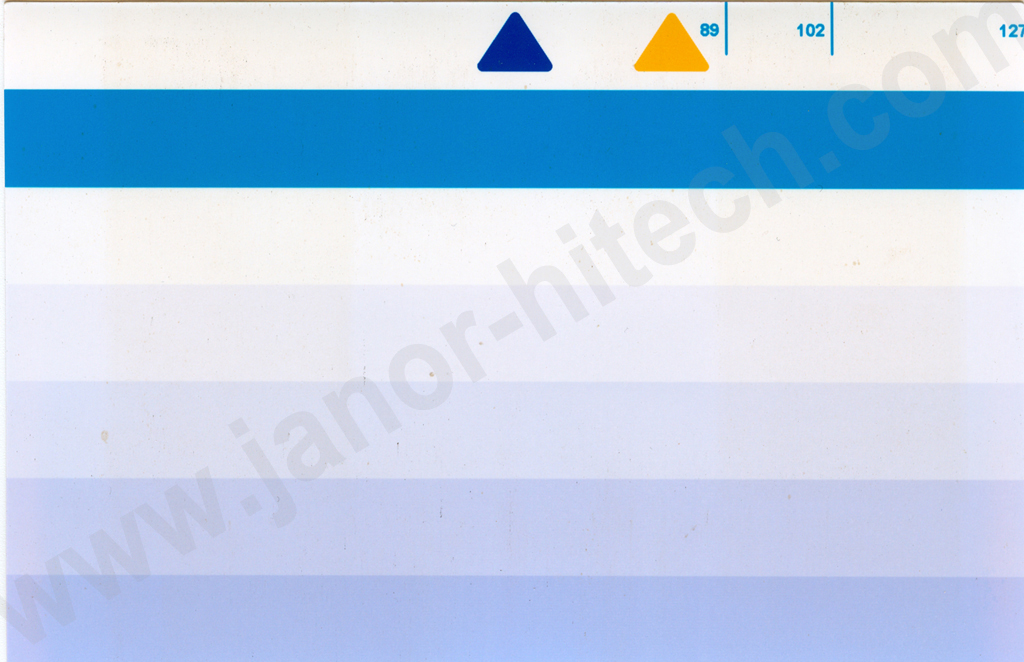

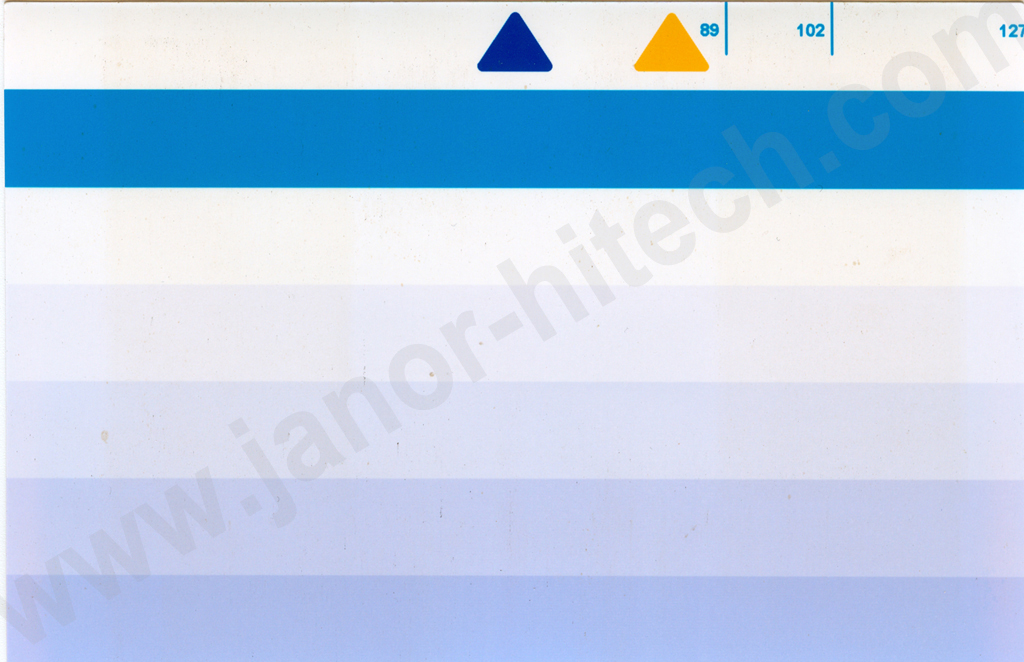

ALL |

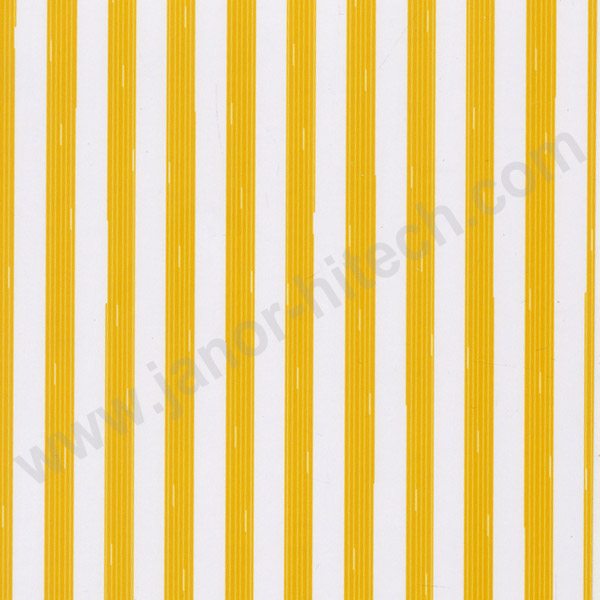

Yellow line |

|

Light quantitative change weak enough to keep synchronization

Sometimes lost synchronous signal (slight) |

ALL

( Not including QSS-30 Series) |

Yellow line |

|

Light quantitative change weak enough to keep synchronization

Sometimes lost synchronous signal (serious) |

ALL |

Color change |

|

After minilab working 4 hours,the color changed lightly

(within 12 key difference ratio steps) .

If this happen everyday ,the blue laser must be damaged.

|

ALL ( Not including QSS-30 Series) |

Laser weak |

|

The laser light arrived in to paper is too weak

Reason 1: laser light is too weak

Reason 2: Aom driver PCB distribution signals of

the amount of

light was abnormal caused by light assignment insufficiency

You can exchange Aom driver to judgment

if changed Aom driver pcb the photo become normal

it's means Aom driver is damage.otherwise,

the laser head was damage

|

ALL ( Not including QSS-30 Series) |

Laser weak |

|

The laser light arrived in to paper is too weak

Reason 1: laser light is too weak

Reason 2: Aom driver PCB distribution signals of

the amount of

light was abnormal caused by light assignment insufficiency

You can exchange Aom driver to judgment

if changed Aom driver pcb the photo become normal

it's means Aom driver is damage.otherwise,

the laser head was damage

|

ALL ( Not including QSS-30 Series) |

Laser weak |

|

The laser light arrived in to paper is too weak

Reason 1: laser light is too weak

Reason 2: Aom driver PCB distribution signals of

the amount of

light was abnormal caused by light assignment insufficiency

You can exchange Aom driver to judgment

if changed Aom driver pcb the photo become normal

it's means Aom driver is damage.otherwise,

the laser head was damage

|

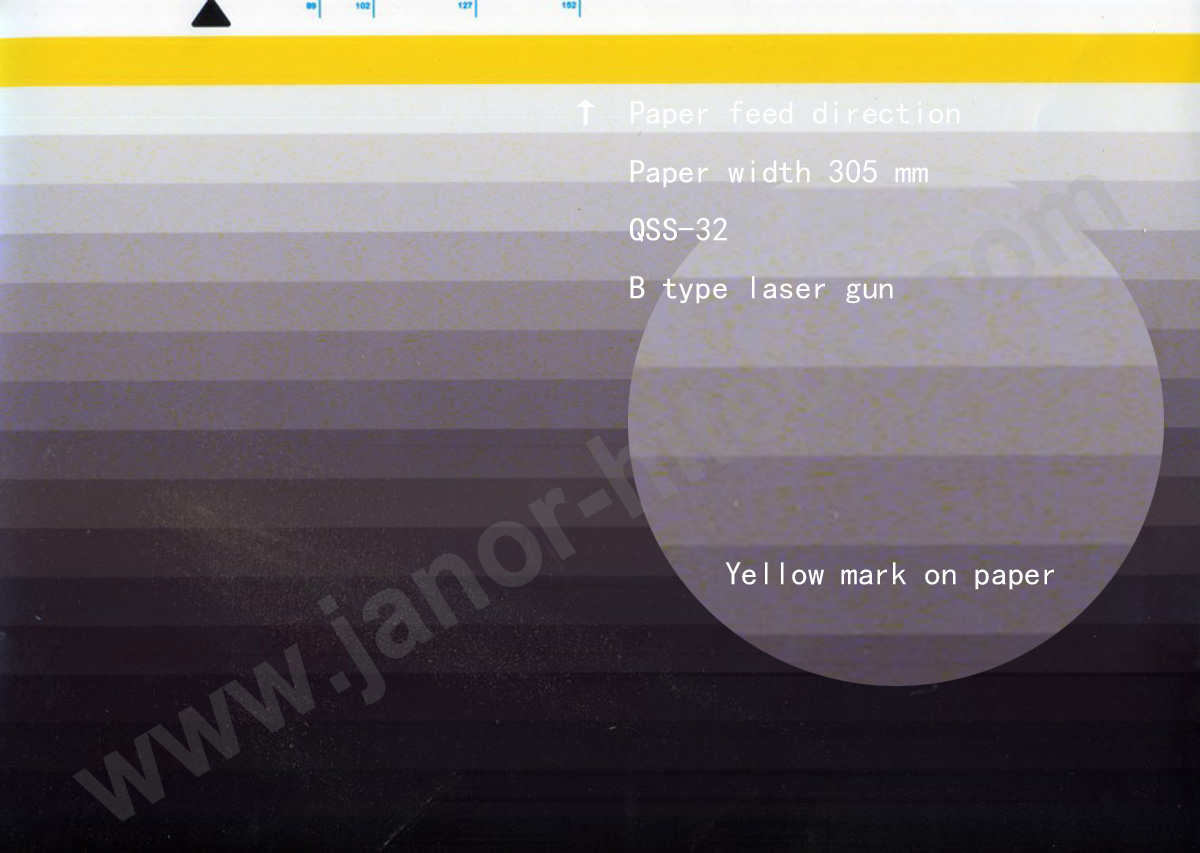

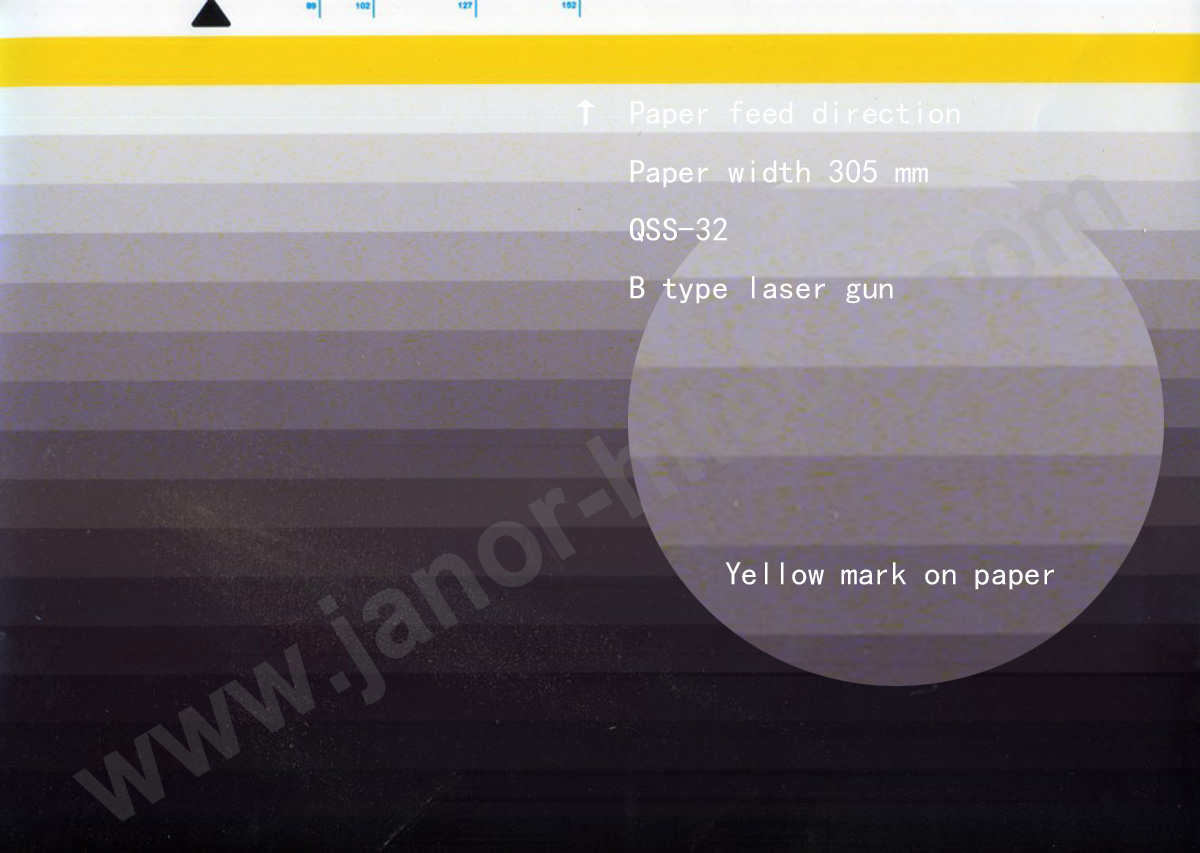

ALL |

Laser noise |

|

Very slight yellow ripple

noise

Bule laser work is not stable |

ALL |

Laser noise |

|

Yellow dot

Bule laser work is not stable

Bule laser work is not stable |

ALL |

Laser noise |

|

Magenta dot

Green laser work is not stable

Green laser work is not stable |

ALL |

Yellow dot |

|

Yellow dot on print

Blue laser noise

Blue laser work is not stable |

ALL |

Yellow dot |

|

Yellow dot

Blue laser noise

Blue laser work is not stable |

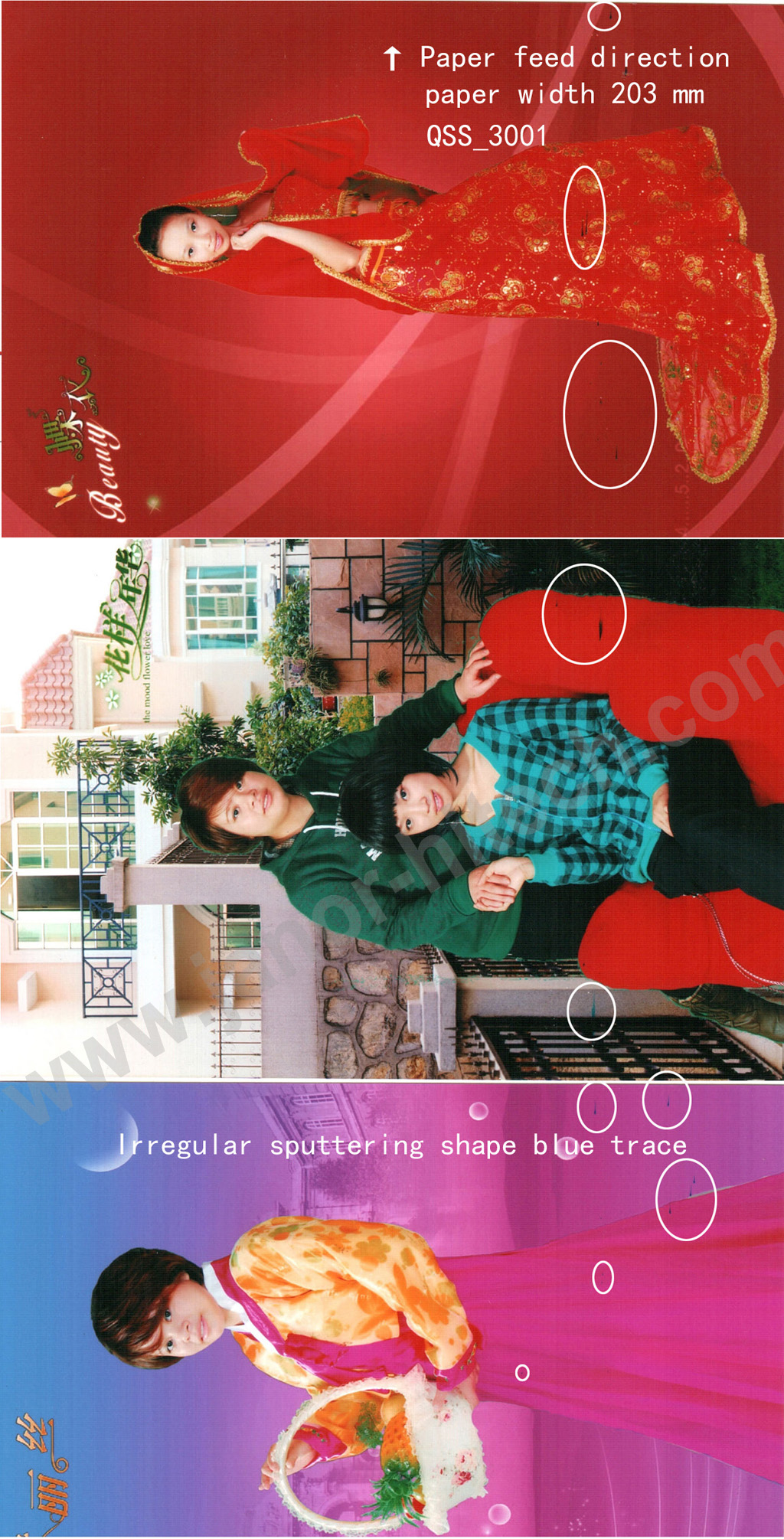

QSS-30 |

Abnormal dot |

|

Blue dot on print

Means physical damaged on the parts of paper path.

|

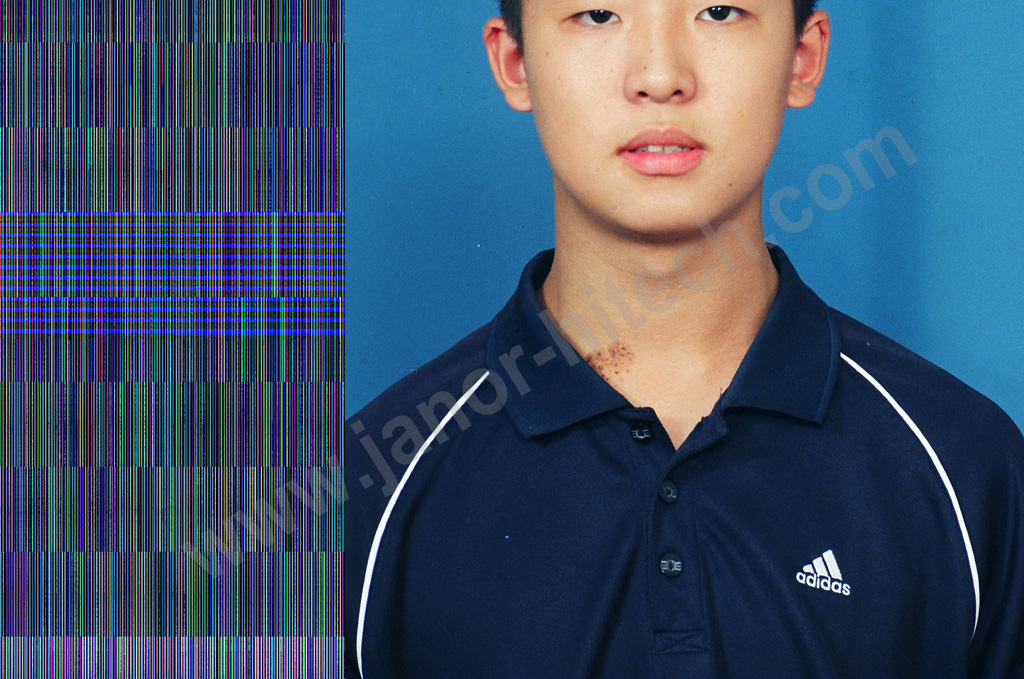

QSS-29 |

Abnormal

dot and line |

|

Color dots and lines on print,

Means abnormal image processing, you should change the image processing PCB. |

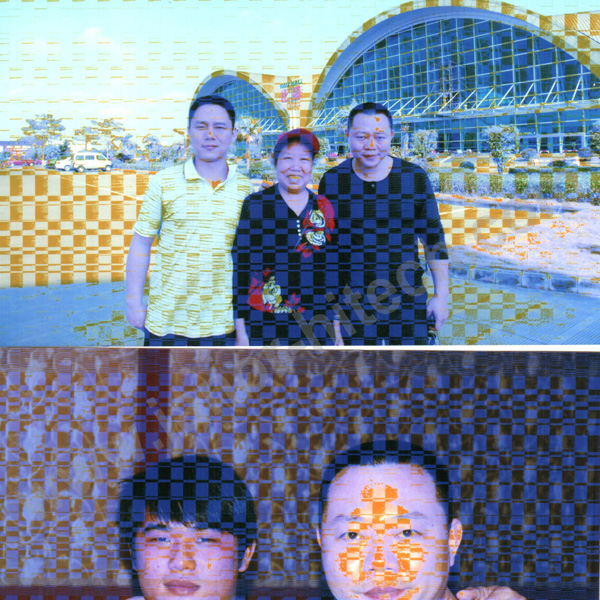

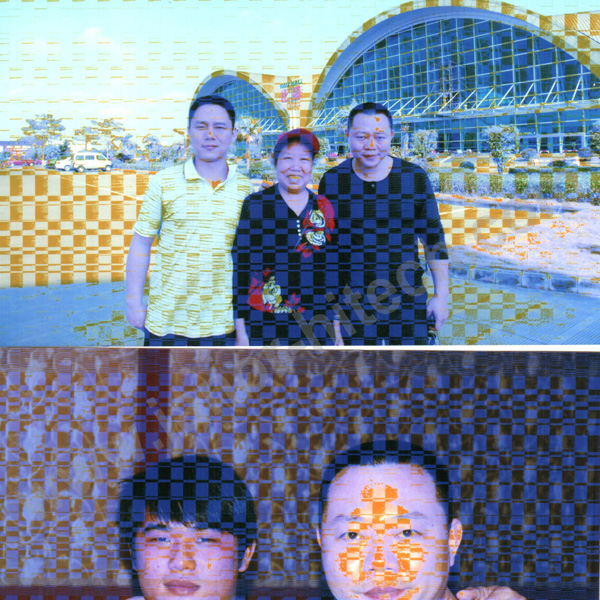

QSS-30 |

Abnormal

image |

|

Abnormal image ( left)

Means abnormal image processing, you should change the image processing PCB. |

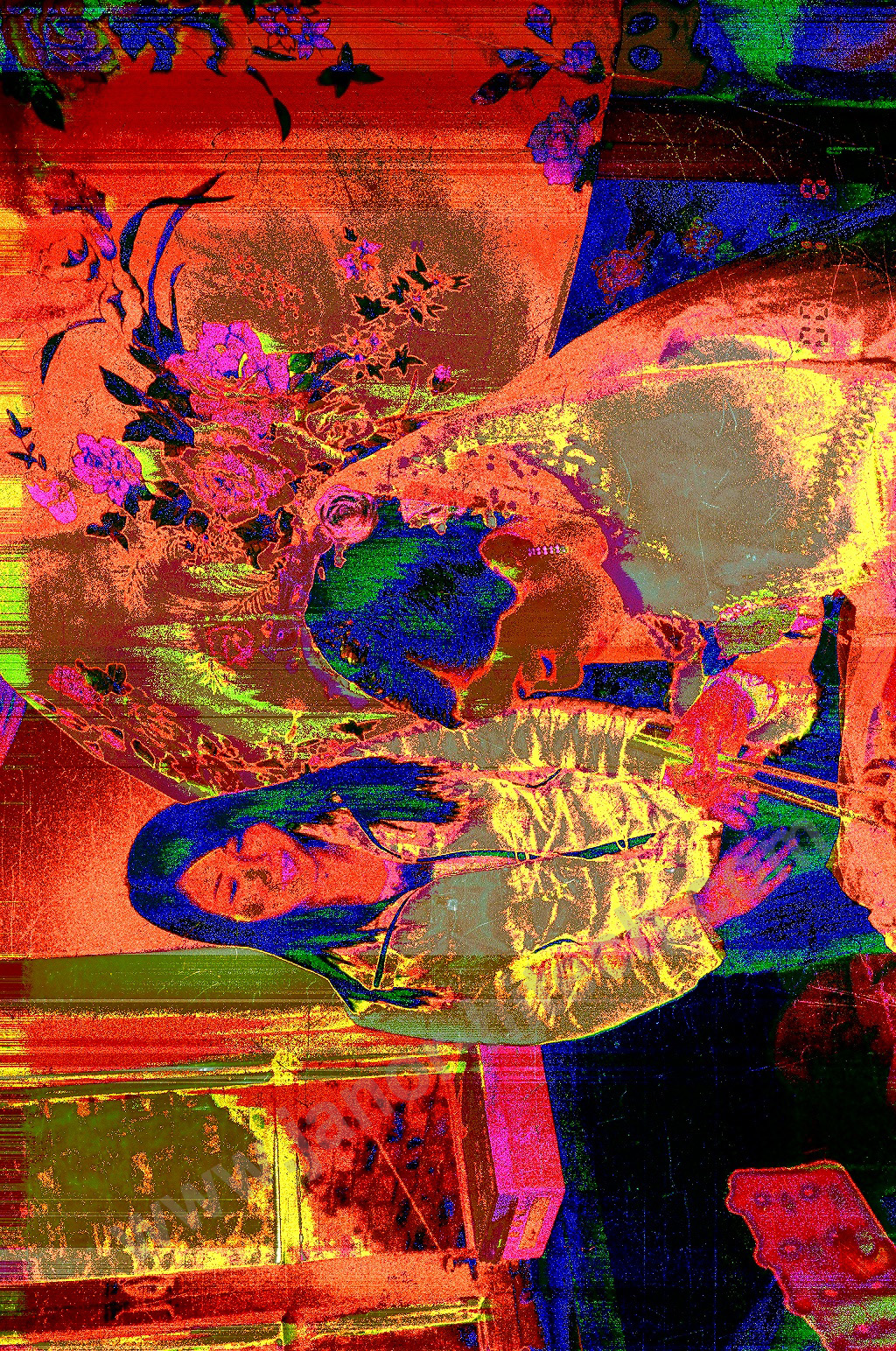

QSS-30 |

Image

processing

abnormal |

.jpg) |

Abnormal image ( left)

Means abnormal image processing, you should change the image processing PCB. |

QSS-30 |

Abnomal

color

|

|

Abnormal image ( left)

Means abnormal color management, you should replace the profile in main program. |

QSS-29 |

Image

processing

abnormal |

|

Image

processing

abnormal

abnormal image ( left)

abnormal communication,clean the Fibers |

QSS-29 |

Abnorma Image

|

|

Image

processing

abnormal

means abnormal image processing, you should change the image processing PCB. |

QSS-30 |

Ghost shadow |

|

Red laser gun damage.

Replace red laser gun.

|

QSS-30

QSS-29 |

High light |

|

Abnormal image ( left)

Means abnormal color management, you should replace the profile in main program. |

QSS-29 |

Abnomal

color |

|

Abnormal image ( left)

Means abnormal color management, you should replace the profile in main program. |

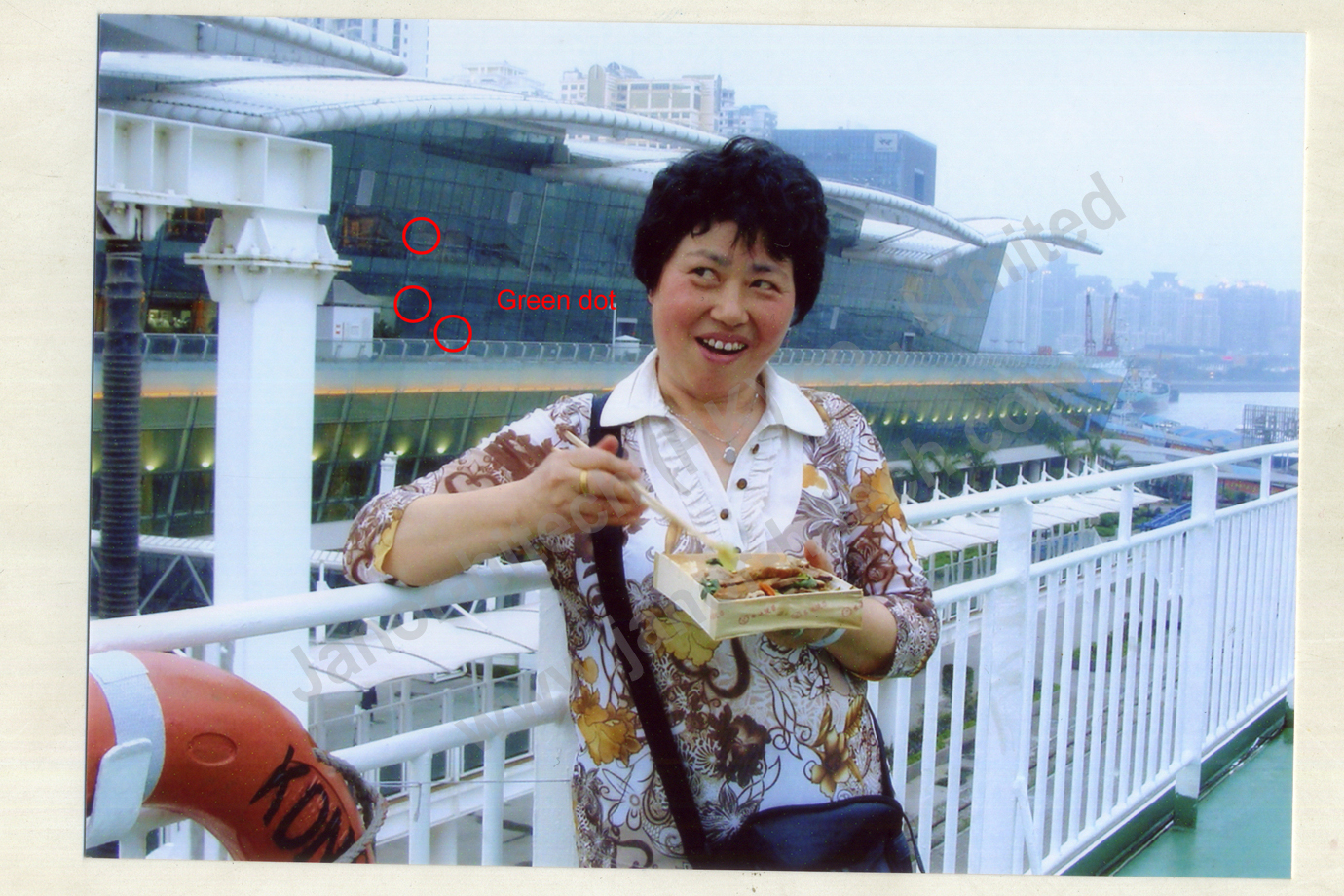

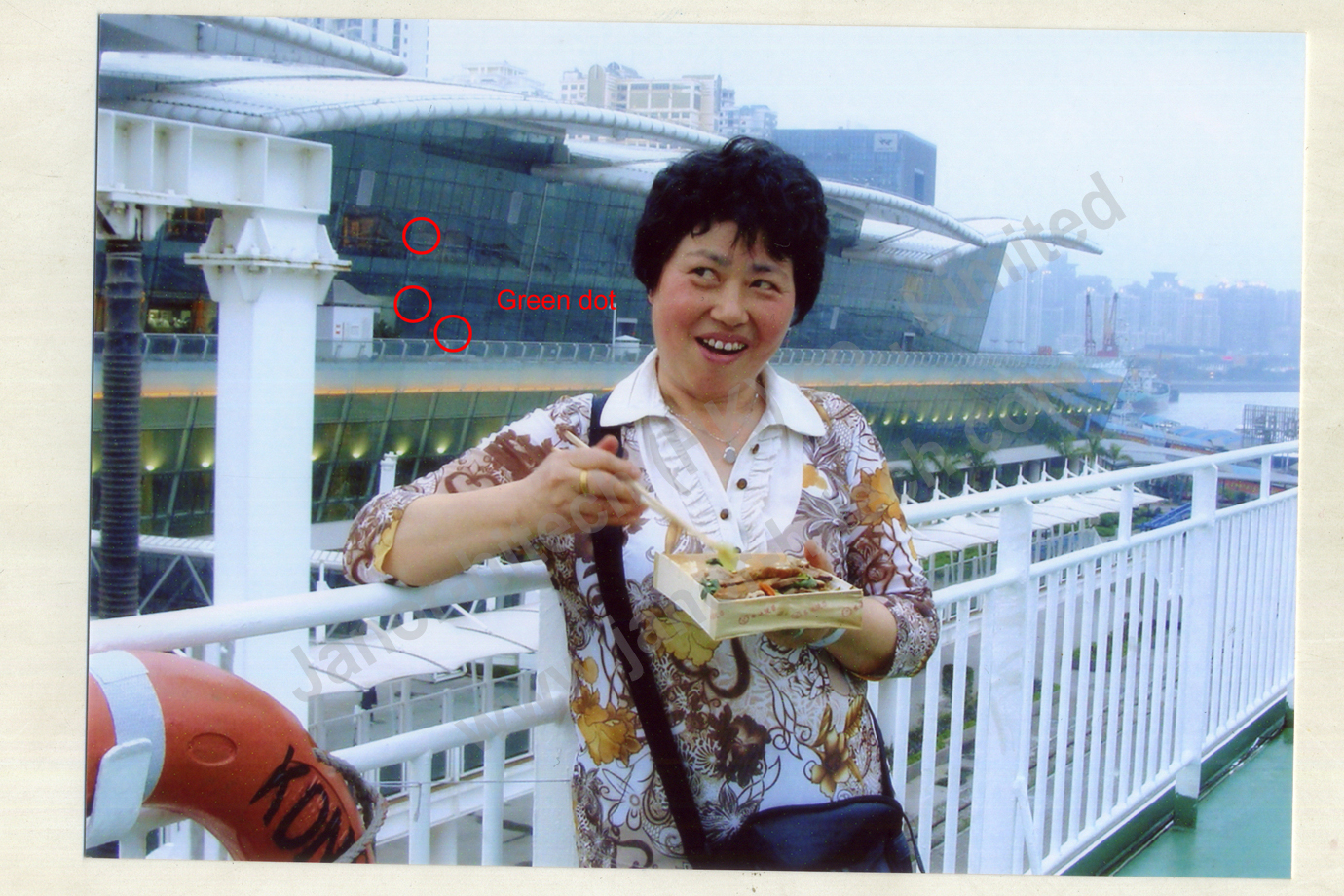

QSS-29 |

Green dot |

|

green dots regularly

means abnormal image processing, you should change the image processing PCB. |

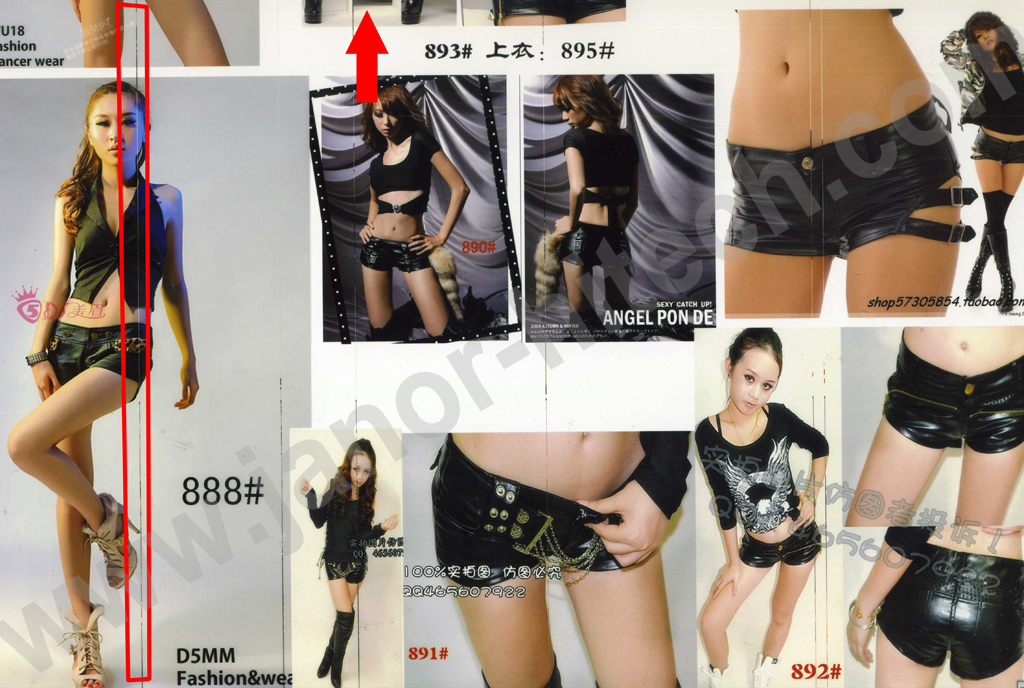

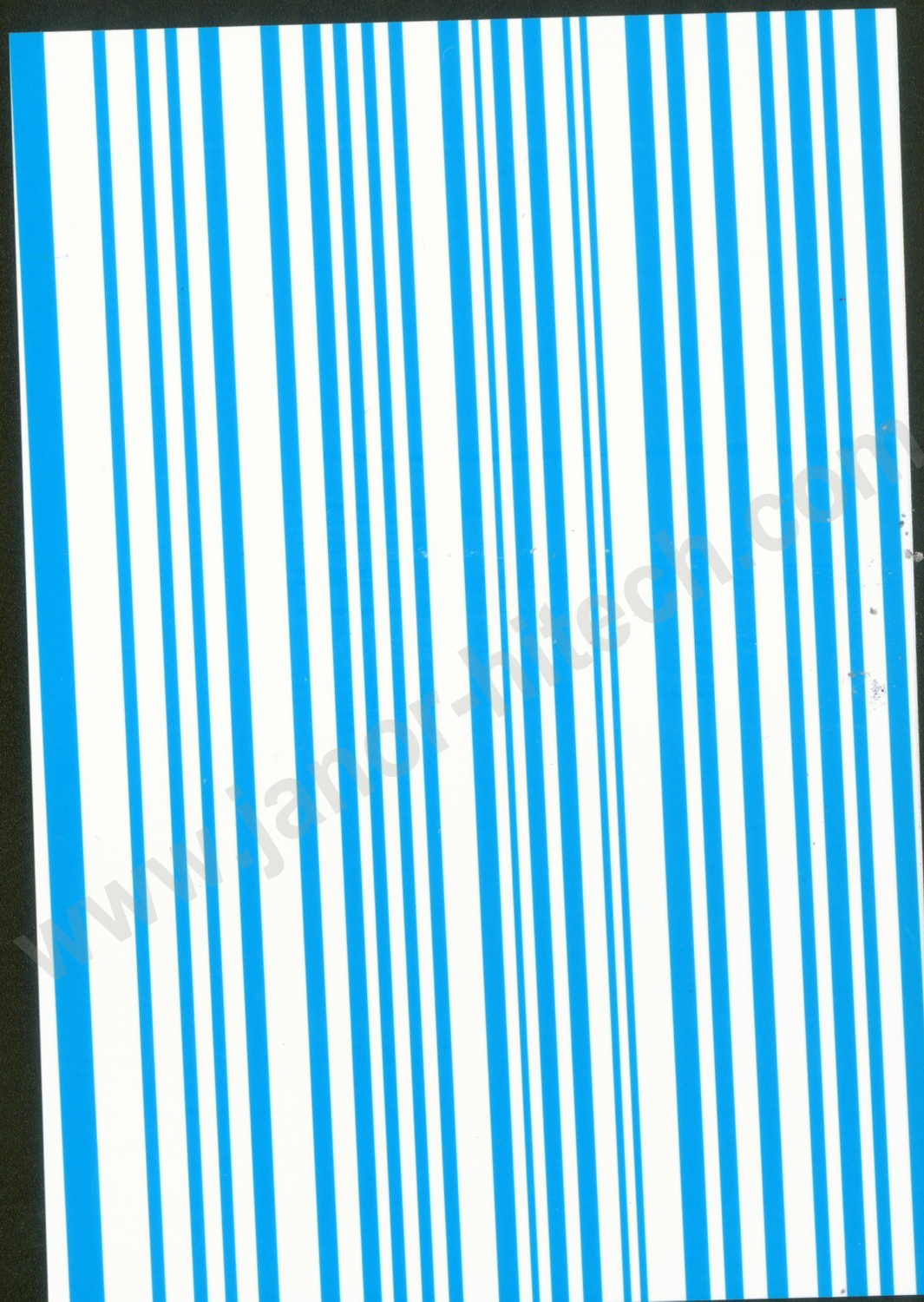

ALL |

Color line

|

|

Blue laser synchronous signal lost

Reason 1:blue laser light is too weak

Reason 2:blue Aom driver PCB distribution signals of the amount of

light was abnormal caused by light assignment insufficiency

You can exchange Aom driver to judgment

if changed Aom driver pcb the photo become normal

it's means Aom driver is damage.otherwise,

the laser head was damage |

ALL |

Color line

|

|

Red laser synchronous signal lost.

The red laser light arrived in to paper is too weak

Reason 1: red laser light is too weak

Reason 2:red Aom driver PCB distribution signals of the amount of

light was abnormal caused by light assignment insufficiency

You can exchange Aom driver to judgment

if changed Aom driver pcb the photo become normal

it's means Aom driver is damage.otherwise,

the laser head was damage |

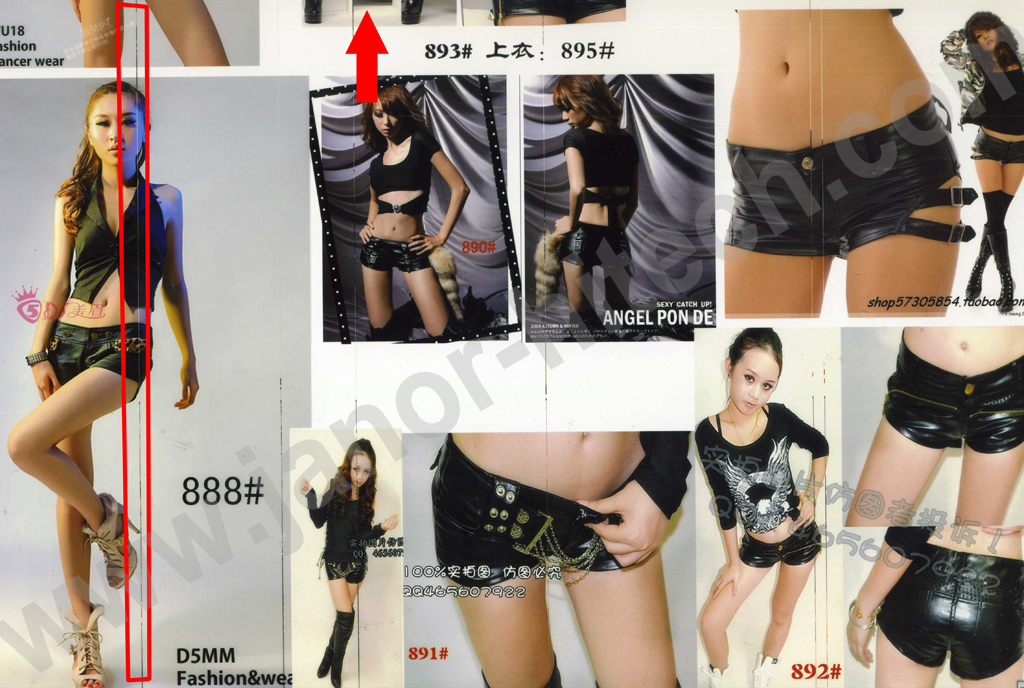

QSS-30 |

Abnomal color and color line |

|

Reason :red Aom driver PCB distribution signals of the amount of

light was abnormal caused by light assignment insufficiency

You can exchange Aom driver to judgment

|

.jpg)